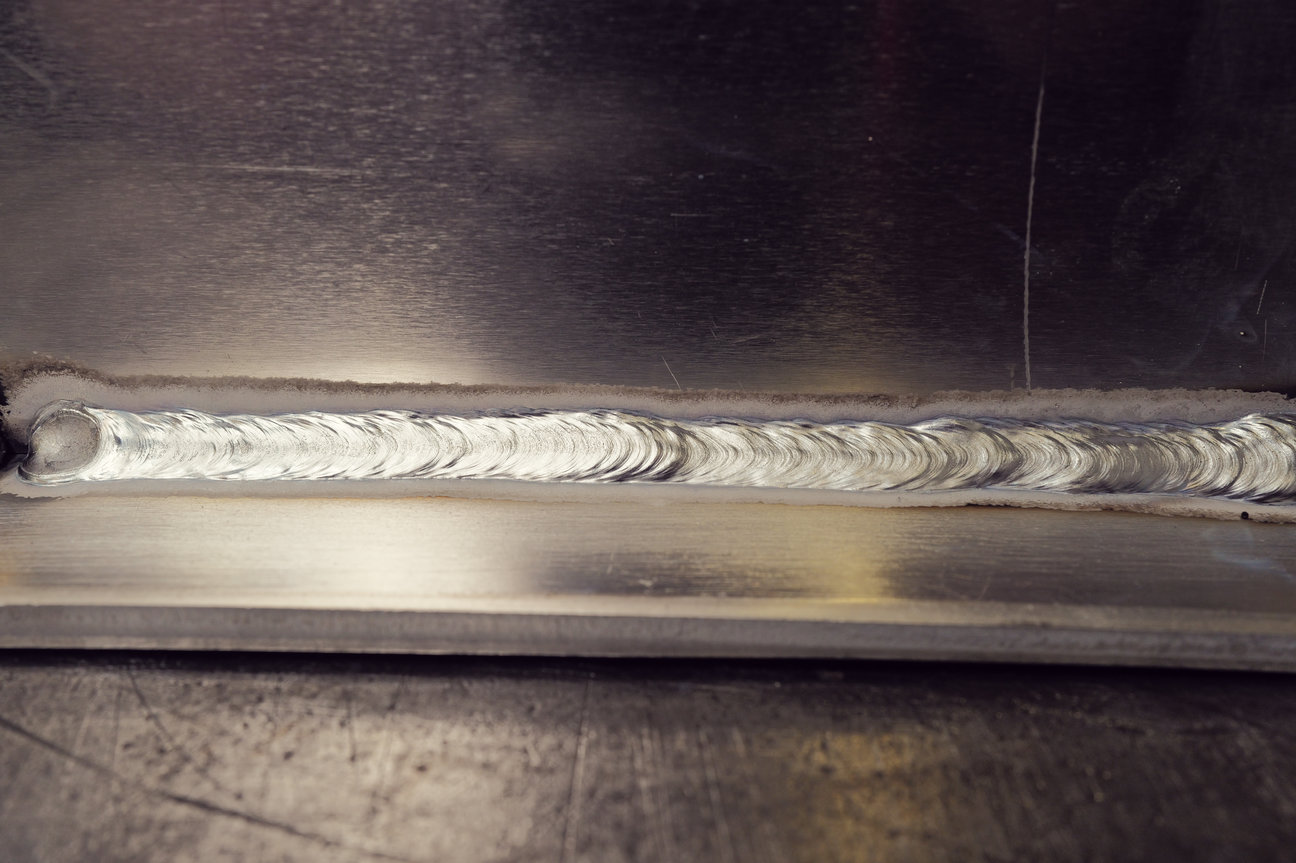

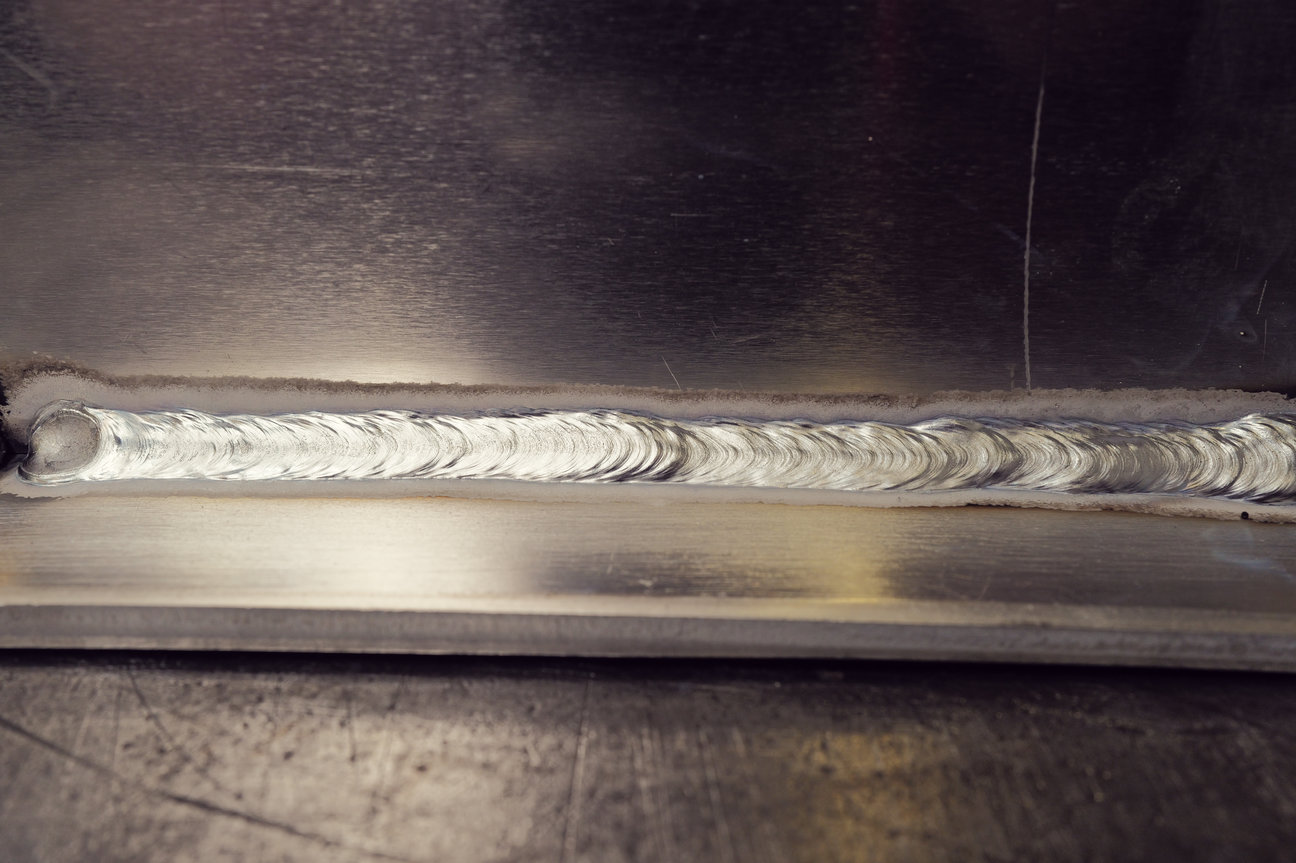

No Weaving

If no weaving (forward–backward motion along the welding direction) is applied, the molten pool cannot degas sufficiently. This significantly increases the risk of porosity in the weld seam. Weaving is especially important for wider welds or materials with high gas solubility (e.g. aluminum) to ensure consistent weld quality.

How to avoid it:

- Perform steady weaving (forward–backward motion in welding direction)

- Maintain consistent speed and clean hand guidance

- Adjust parameters to match material and joint design

- Thoroughly clean surfaces to reduce additional porosity risks